Requirement for drawings and models of castings

Requirement for drawings of castings

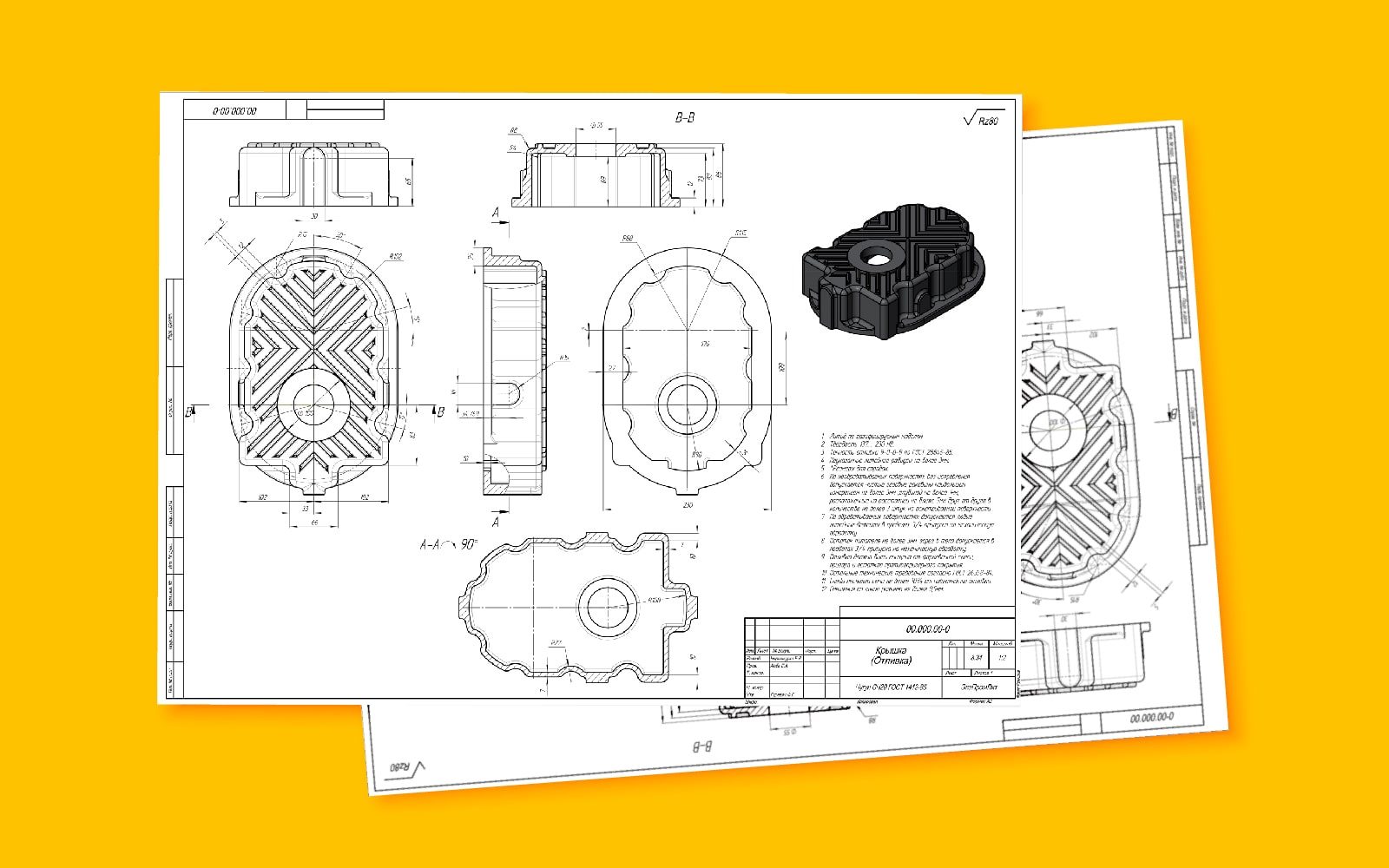

A drawing of a casting is a mandatory technological document, since according to the drawing, the control and acceptance of finished castings by the Quality Control Department or the customer, as well as their certification, are carried out. A drawing of a casting with technical requirements must contain all the data necessary for the manufacture, control and acceptance of the product.

Requirements for the drawing of the casting:

- The configuration of the casting with all geometric dimensions, as well as the designation of the contours and main dimensions of the part (to indicate the location and allowance for machining).

- Grade of alloy from which the castings will be made, as well as substitute material.

- Casting responsibility group.

- Class of accuracy, dimensional tolerances of the casting.

- The hardness of the material.

- Admissibility, type of casting defects in the casting.

- Placement and rest of the feeder on the casting.

- The presence of other technical requirements for the casting.

Model requirement

The model has a special, important role in obtaining high-quality casting.

Special attention is paid to the expanded polystyrene model, these are:

- the bulk density of the model (that, when pouring a mold with a liquid melt during the process of thermal destruction of the model, excessive release of gaseous products occurs, which, in turn, have a generally negative effect on obtaining a casting of the appropriate quality, and also contribute to the occurrence of a number of casting defects, such as: "Gas sink", "underfilling", etc. The mechanical properties of products are reduced.

- inadequacy of individual parts of the model, rough surface of the model, melting of the model surface, shrinkage of granules, warping of the model - all these defects of the expanded polystyrene model are not permissible in the further manufacture of the casting, because when pouring, the metal fills the cavity of the displaced model, repeating its geometry in the smallest detail.