Casting technology for iron and steel

The Ecopromlit enterprise talks about the technologies that are used in the casting of iron and steel

This technology makes it possible to manufacture parts of high complexity, without the cost of manufacturing molds, which are used in large-scale or mass production of models

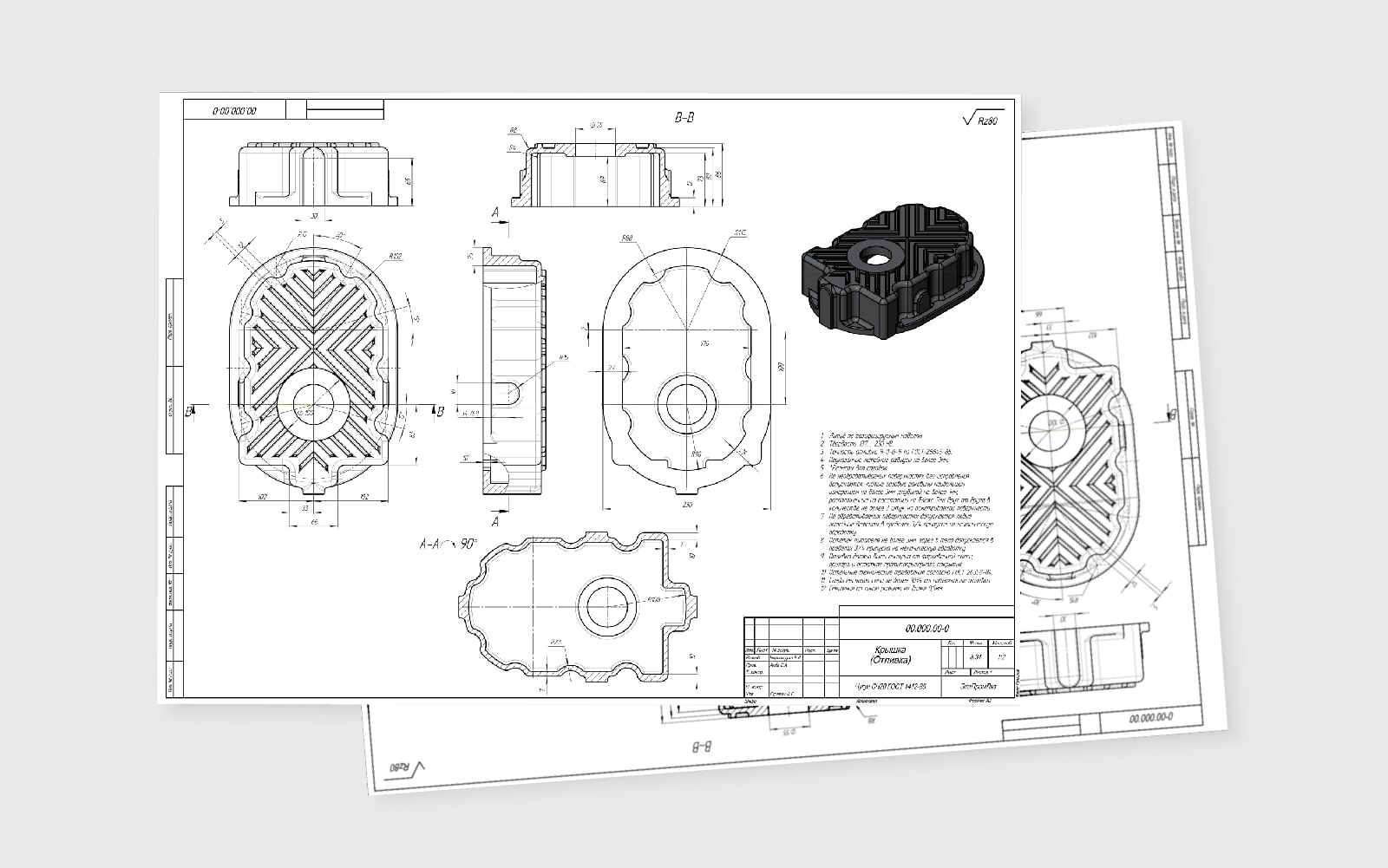

A drawing of a casting is a mandatory technological document, since according to the drawing, the control and acceptance of finished castings by the Quality Control Department or the customer, as well as their certification, are carried out

For the production of castings of cast iron, steel and non-ferrous metals, the Ecopromlit plant uses ready-made casting materials obtained by metallurgical method from various fossil ores.

Endless processing is the most optimal processing of casting castings from cast iron and steel, which is used at the Ecopromlite plant.

Casting cast iron and steel by the LGM method is a way to obtain high-quality castings, which is applied at the Ecopromlite plant.

In the production of casting forms Ecopromlit uses the opponent coating of its own development.

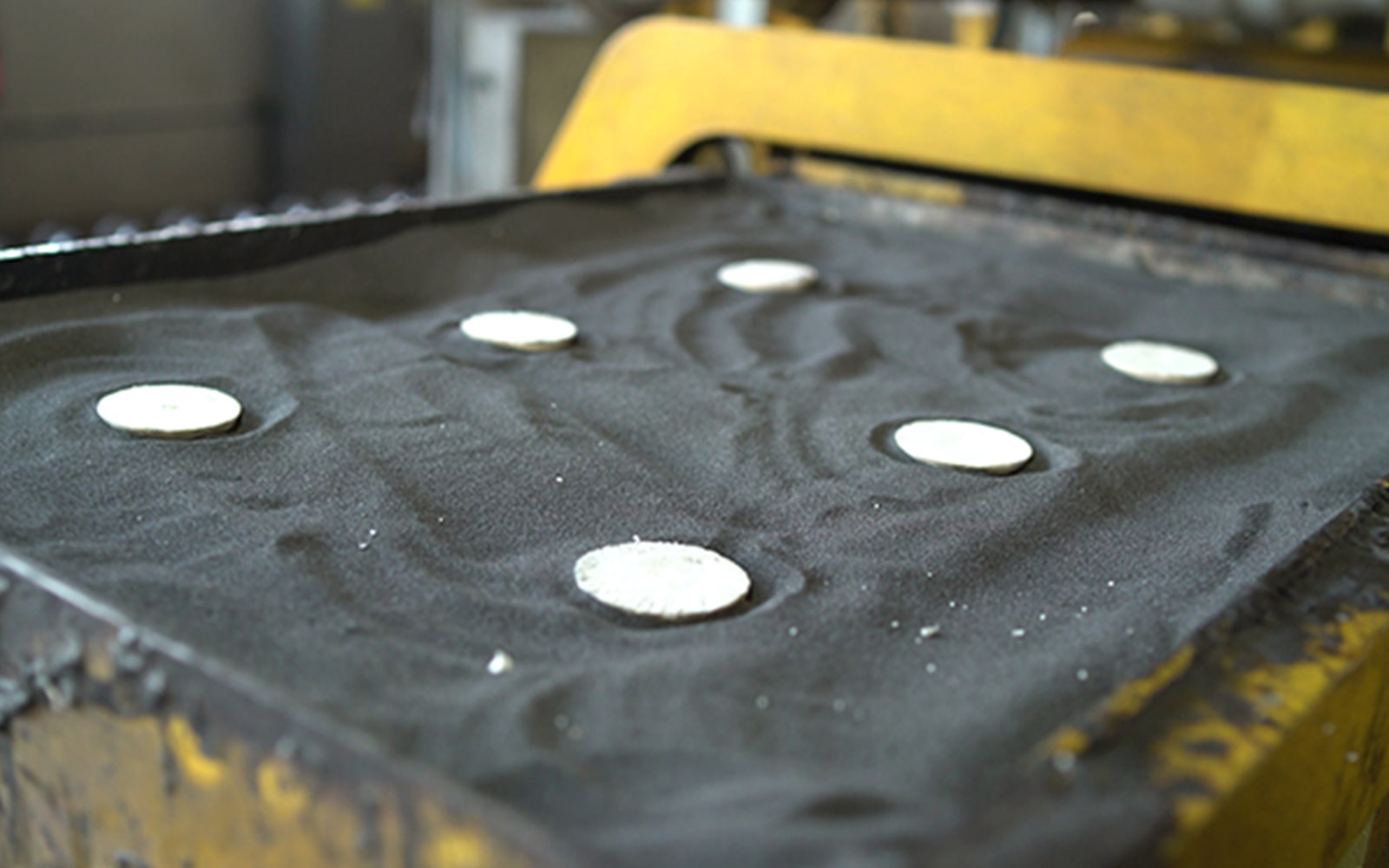

The molding in the sand is the most important operation of the process of casting, providing the quality of the future casting.